What is the Solution to Landfilling?

Waste to Energy

GLOBAL RESERVES LLC

Where do you

want to live?

Facilities

ISSUE

LANDFILL

Liquid Phase

AIR

WATER

LAND

AIR

WATER

LAND

Methane

Carbon Dioxide

Hydrogen Sulfide

Leachate & System Problems

Problem #1

Drainage

Problem #2

Linear Rips

Location

Land Devaluation

Long Term Effect

(Accountability)

Accounts for approximately 40 - 65% of Landfill emissions. Highly flammable. Even with the most structured landfill it is estimated that 50% of methane gas escapes into the air.

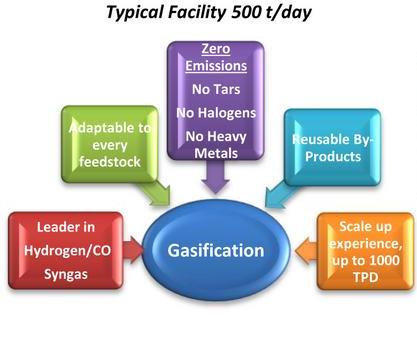

During the extended liquid phase process the temperature is regulated to reach a maximum 200° Celsius. There is no need for post cleanup of the combustible gasses since no pollutants are created at the liquid phase stage.

Accounts for approximately 40 - 60% of Landfill emissions.

Our patented Next-Gen process eliminates all tar, halogens, chlorine, mercury and other heavy metals during the liquid phase. The lower temperatures and cleanup system provide “zero emissions” from the facility thereby becoming an attractive source for “ZERO EMISSION CARBON CREDITS.”

Other landfill gases are produced by bacteria breaking down organic material and are called reduced sulfur gases or sulfides (Example: Hydrogen Sulfide H2S). These are toxic and can cause various types of medical problems. This provides the rotting smell from landfills.

When municipal solid waste (MSW) comes in contact with liquid, leachate is formed. Such leachate contains a myriad hazardous and otherwise deleterious chemicals which if introduced into groundwater would impair or destroy the ability to use the groundwater and aquifer.

Biological growth, chemical precipitates, and “fines” derived from the wastes all tend to cause the leachate collection system to plug.

One of the most significant problems with leachate collection systems’ functioning as designed is that the HDPE liner, which is the base of the leachate collection system, develops cracks, holes, rips, tears, punctures and points of deterioration. Some of these are caused at the time of installation, and HDPE integrity deteriorates over time.

Land associated with landfilling is always an issue. Large amounts of waste are associated with large populations. In order to develop a landfill of significant size its location may need to be outside of populated areas creating travel logistics for waste vehicles.

The deposition of wastes is allowed very near the landfill property owner’s property line. Under these conditions, the landfill gases, blowing paper, birds, rodents, vermin, etc., associated with the landfill can impinge on adjacent properties.

.

Once a landfill is in place, the decomposition of waste occurs at different levels based on the makeup of the waste. Current post closure monitoring is estimated at 30 years however any major issue (aka, explosion, leakage, etc.) may not have capital allocated for remediation not to mention capital requirements post 30 year landfill anniversary date.

.

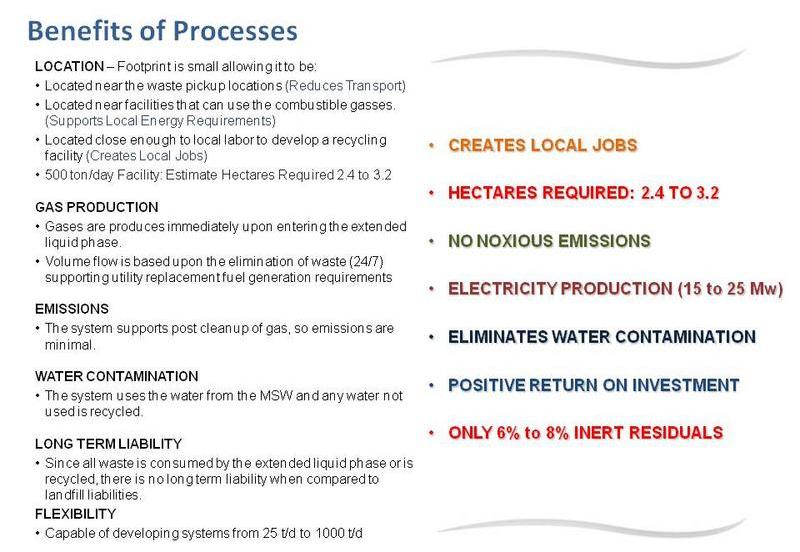

Any water used or extracted from waste during processes is being captured, cleaned through various processes and recycled for reuse, eliminating any type of ground water contamination.

500 Ton/day project: Land Requirement

2.4 to 3.2 Hectares

RESIDUAL PRODUCT: Subject to future recycling strategies, the by product can either be a vitrified slag or a inert ash product. The estimated percentage is approximately:

6% to 8% inert Residuals

The facilities footprint provides for a minimum amount of land when compared to Landfill acreage requirements. When compared to the dynamics of a landfill there is no comparison. Facilities can also be strategically located in various areas to support a reduction of transportation requirements. Additionally, local job creation supports community outreach intended to support local economies.

Liquid Phase

Leader in

Hydrogen/CO

Gas